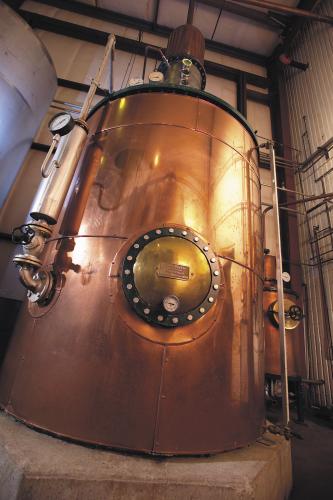

Why Copper Stills Make A Difference

When a vendor or master distiller comes in to taste me on their whisky, I always here them talk about the how the copper still really makes a difference, but when I ask them specifically why, they say something vague like, "the shape makes a difference in the flavor" or "it enhances the spirit." WTF? That doesn't help me understand the distillation process as someone who is trying to get a grip on this whole artisan whisky thing. However, having finally secured a copy of Andrew Jefford's Peat Smoke & Spirit, is was clearly spelled out for me in a way that I think everyone can understand (which is why I am going to quote it on this blog).

The basic function of copper is to help filter out the impurities in the whisky. While alcohol boils at 78.5 degrees, so do a bunch of other other chemicals, such as Methanol, which will make you blind if you drink too much of it. Great distillers are able to capture the purest of spirits in their still and the "fine, microscopic hairiness of copper, and its sociable, reactive nature...makes it such an ideal distilling material." Douglas Murray is quoted as saying, "If you look at copper under a microscope it looks like a scouring pad. The result is that, as the spirit vapour passes over it, copper stops that vapor for what we call a 'chat.' The more slowly the vapour passes over the copper, the more the chemical impurities in the spirit attach themselves to the fine scouring-pad threads. The longer the chat does on, in other words, the lighter the spirit."

This also explains why the shape of the lyne arm - the neck of the still where the vapor collects - is also so influential. The length and width of the lyne determine the amount of contact the condensing spirit has with the copper!

That makes total sense to me. I now understand why copper stills are important.

-David Driscoll